Explore the Fascinating World of GELITA

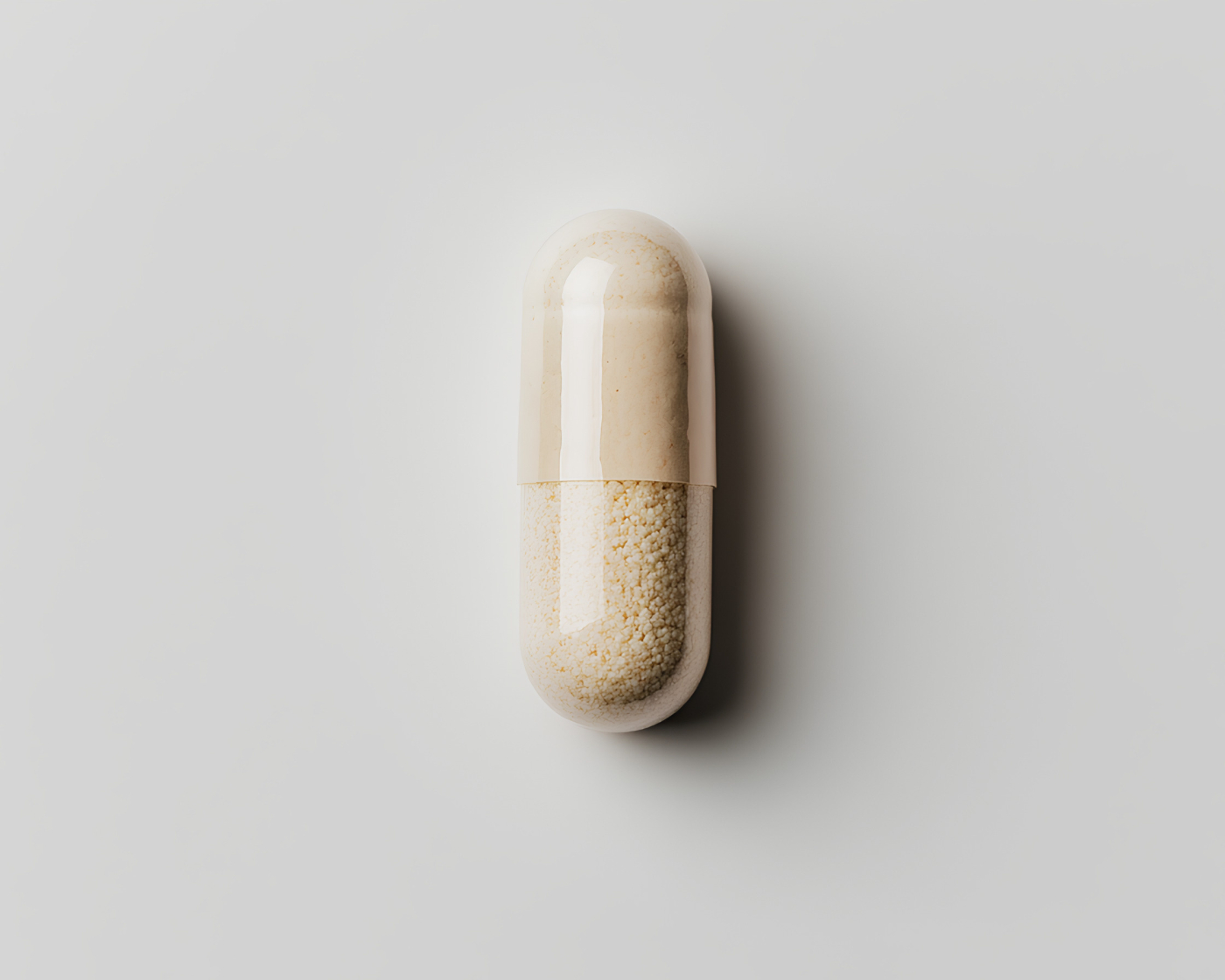

We are gelatin, collagen, and collagen peptide experts. These natural, pure and allergen-free clean-label ingredients play a key role in good food, healthy living, and technical innovation.

We believe in natural solutions, science, and the power of creativity. Driven by innovation, our guiding principles are excellence, expertise, and the highest service levels. Consumer trust and transparency are part of our corporate DNA, and we work hard to make our vision come true: Improving quality of life.

With our global presence, we serve the food and drinks industry and are active in the health and nutrition, pharmaceutical and medical sectors, and a wide range of exciting technical applications.

Want to discover more? Take a tour of our website and discover why the world’s leading manufacturers and millions of consumers trust us. Welcome to GELITA.