Endotoxin Controlled Gelatins for Bioscience

In the pharmaceutical, medical device and healthcare industries, endotoxin control is critical to ensure product safety and patient well-being.

With MEDELLAPRO®, GELITA offers pure, highly specialized pharmaceutical grade gelatins that provide optimal stability, are biocompatible by nature, and facilitate the development of safe and effective biomedical products.

Why MEDELLAPRO®?

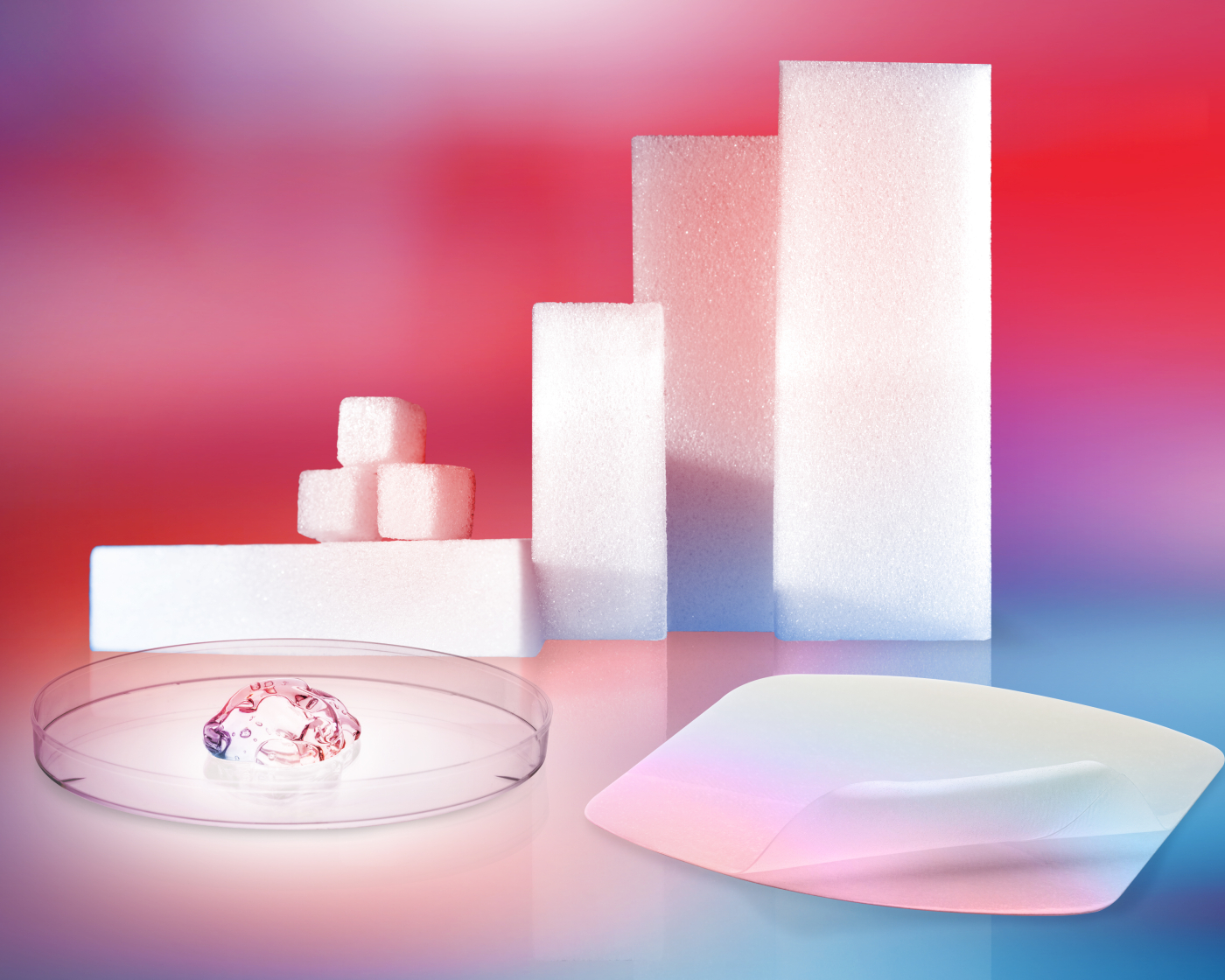

Life Science Applications

The MEDELLAPRO® range includes for instance several low endotoxin medical grade gelatins for various medical devices.

- Hemostatic Agent: Enhances blood clotting during surgery

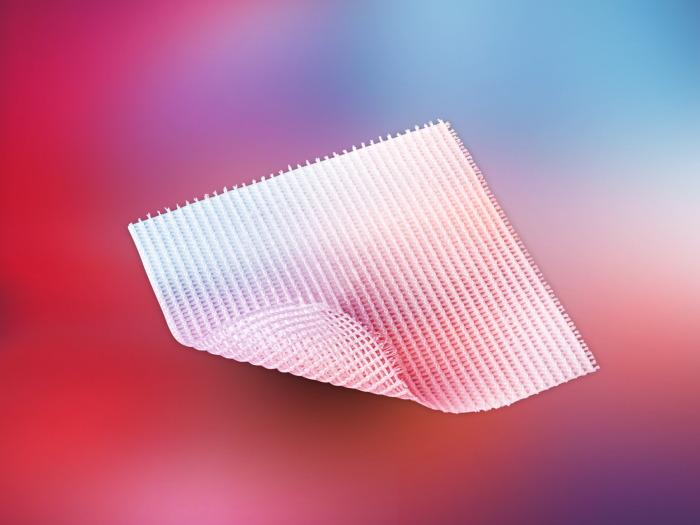

- Wound Care: Supports cell proliferation and tissue regeneration, and protects against contaminants

- Blood Plasma Expander: Safely increases blood volume in emergencies

- Embolization: Acts as a temporary artificial embolus and drug carrier

- Drug Delivery Systems: Enables controlled, targeted agent release

- Diagnostic Imaging: Effective in contrast agents for medical imaging, such as MRI and ultrasound

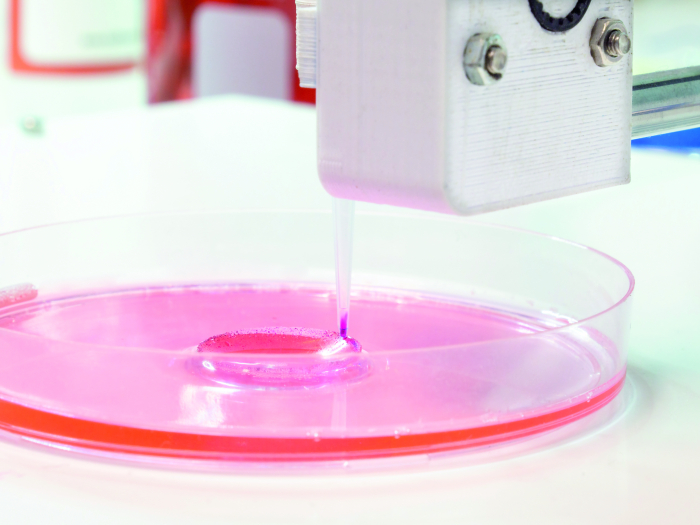

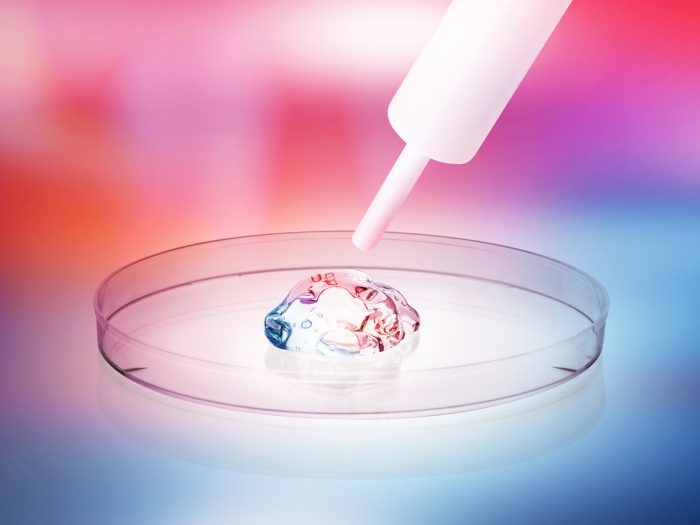

3D Bioprinting and Cell Culture

MEDELLAPRO® gelatins are the ideal biomaterial for 3D bioprinting and cell culture in human tissue engineering. They can be used for a variety of different applications:

- Tissue Engineering via 3D Bioprinting: Mimics tissue characteristics and supports cell adhesion, proliferation and differentiation

- Cell Culture Substrates: Facilitates cell adhesion to surfaces and promotes cell growth

- Cell-Cultured Meat: Supports the production of artificial meat through its safe use as food and enhances cell adhesion with its numerous integrin-binding sites.

Compliant With International Standards

MEDELLAPRO® is produced in accordance with ISO 9001:2015; FSSC 22000 and corresponding EU and FDA food regulations. It is therefore declared “fit for human consumption”.

Furthermore, as pharmaceutical grade gelatin, MEDELLAPRO® complies with the current Ph. Eur. and USP Gelatin Monograph. Endotoxin levels, expressed in Endotoxin Units (EU/g), are controlled, with different specified endotoxin levels