GELITA’s newest innovation, MEDELLAPRO® Ultra Low Endotoxin Gelatin, redefines the standards for bioprinting-grade gelatin. Engineered for high-purity applications in bioscience, tissue engineering, and regenerative medicine, MEDELLAPRO® combines exceptional gel strength with ultra-low endotoxin levels (≤ 10 EU/g), setting a new benchmark for reliability and performance in a rapidly growing bioprinting landscape.

What is 3D Bioprinting?

3D bioprinting enables the layer-by-layer fabrication of living tissues using bioinks composed of cells, biomaterials, and growth factors. This process replicates the architecture and functionality of human tissue, supporting breakthroughs in drug discovery, regenerative therapies, and organ modeling.

Bioprinting merges engineering precision with biological complexity, enabling the creation of skin, cartilage, and vascularized tissue while offering faster, animal-free preclinical testing options.

The global 3D bioprinting market is projected to grow at more than 15% annually, reaching USD 6.3 billion by 2031 (Straits Research, 2024).

What are the Biggest Challenges?

3D bioprinting is redefining regenerative medicine, but two critical challenges remain: scalability and mechanical integrity. Printing human-scale tissues is slow and risks reduced cell viability during extended processing times (Vijayavenkataraman et al., 2023).

Bioinks must balance printability with structural stability—too soft and constructs collapse; too stiff and cells cannot thrive. Advances in hybrid hydrogels and smart crosslinking strategies are enabling gels that combine structural precision with biological compatibility (Chan et al., 2020).

Why Gelatin is Essential in Bioprinting

Gelatin, a collagen derivative, is widely used in bioprinting due to its biodegradability, biocompatibility, and cell-supportive matrix. It mimics the extracellular matrix and promotes cell adhesion, migration, and differentiation.

When modified into Gelatin Methacryloyl (GelMA), gelatin gains enhanced mechanical stability and structural accuracy after photocrosslinking (Gopinathan & Noh, 2018). This makes gelatin a key material for scaffolds, organ-on-a-chip models, and drug delivery systems (Gungor-Ozkerim et al., 2018).

The Importance of Endotoxin Control

Endotoxins (lipopolysaccharides, LPS) can trigger strong inflammatory responses even at very low concentrations. In biomedical research and cell culture, high endotoxin levels compromise reproducibility and reduce cell viability.

Thanks to a specialized purification process, MEDELLAPRO® achieves ≤ 10 EU/g, ensuring minimal immune activation and consistent batch-to-batch quality.

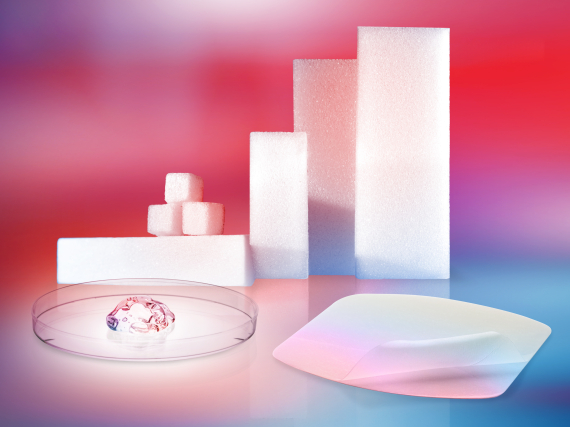

Introducing MEDELLAPRO® Ultra Low Endotoxin Gelatin

MEDELLAPRO® Ultra Low Endotoxin Gelatin is available in multiple grades derived from porcine skin and bovine bone. All grades offer high gel strength (230–270 g Bloom), ultra-low endotoxin levels (≤ 10 EU/g), and traceable European raw materials.

Product Specifications:

| Product | Origin | Endotoxin Level (EU/g) | Gel Strength (g Bloom) | Applications |

|---|---|---|---|---|

| MEDELLAPRO® 10 P 250 | Porcine skin | ≤ 10 | 230–270 | Bioprinting, scaffolds, cell culture, regenerative medicine, drug delivery |

| MEDELLAPRO® 10 B 250 | Bovine bone | ≤ 10 | 230–270 |

Key Benefits:

- Ultra-pure gelatin (≤ 10 EU/g) - minimizes immunogenicity

- Naturally biocompatible, biodegradable, and naturally resorbable

- Batch-to-batch consistency and ISO traceability

- No cytotoxic substances used in production

- Ideal for GelMA synthesis, scaffolds, 3D bioprinting, and regenerative research

Applications Across Bioscience

- 3D bioprinting and scaffold fabrication

- Cell culture systems and tissue regeneration

- Drug delivery and stabilization

- Regenerative medicine and biomedical prototyping

Get in Touch

Overcoming the above mentioned challenges will transform in future bioprinting from a visionary concept into a clinical reality. Discover how MEDELLAPRO® Ultra Low Endotoxin Gelatin can enhance your biofabrication or regenerative medicine solutions.

Get in touch with the experts at the GELITA Pharma Institute (GPI) to explore how this ultra-low endotoxin gelatin can be integrated into your product portfolio and tailored to your specific application needs — bringing us closer to personalized tissues and organs on demand.

References:

Chan, W. W., Lau, B. C. W., & Leung, M. (2020). Additive biomanufacturing with collagen inks. Bioengineering, 7(3), Article 66. https://doi.org/10.3390/bioengineering7030066

Gopinathan, J., & Noh, I. (2018). Recent trends in bioinks for 3D printing. Biomaterials Research, 22, Article 11. https://doi.org/10.1186/s40824-018-0122-1

Gungor-Ozkerim, P. S., Inci, I., Zhang, Y. S., Khademhosseini, A., & Dokmeci, M. R. (2018). Bioinks for 3D bioprinting: An overview. Biomaterials Science, 6(5), 915–946. https://doi.org/10.1039/C7BM00765E

Straits Research. (2024, April). 3D-Bioprinting-Markt: Größe und Ausblick 2023–2031. https://straitsresearch.com/de/report/3d-bioprinting-market

Vijayavenkataraman, S., Yang, Y., & Fuh, J. Y. H. (2023). 3D bioprinting: Challenges in commercialization and clinical translation. Journal of 3D Printing in Medicine, 7(2). https://doi.org/10.2217/3dp-2022-0026