Advancing Regenerative Medicine Through 3D Bioprinting

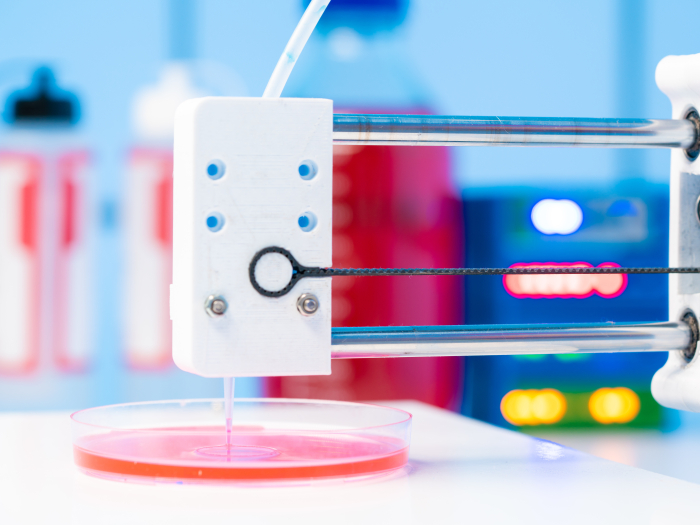

Within the transformative world of 3D printing, an engineering innovation called 3D bioprinting is being used to replace, repair and reconstruct damaged body tissues and even organs. Ocular implants, bone fillers, skin grafts, cartilage replacements, surgical sealants, wound healing devices and more are all being successfully realized. And thanks to its unique properties and particular affinity with the human body, gelatin is playing a key role in this advancement.

3D printed gelatin - based hydrogels and scaffolds have a natural ability to mimic the body’s own extracellular matrix (ECM) and support cell proliferation, adhesion and differentiation. They also offer the benefits of being more economical and less invasive than traditional tissue grafts taken from patients themselves.

Superior Medical Gelatin

With the MEDELLAPRO® product portfolio, we offer a highly specialized gelatin of pharmaceutical grade that has excellent biocompatibility by nature, controlled endotoxin levels, low allergenic potential and high tissue affinity. Due to these characteristics MEDELLAPRO® promotes the regeneration of various tissues, including bone, cartilage and skin, offering a cost-effective solution for superior repair and healing.

Key Benefits:

- Exceptional biocompatibility: Gelatin is derived from natural collagen, so it is extremely compatible with the human body by mimicking the natural extracellular matrix in the tissue

- Ability for high porosity: Helps to facilitate nutrient diffusion and cell migration in vivo

- Good solubility: Gelatin dissolves easily in water, making it easy to use in 3D printers

- Versatile: Delivers 3D printer bio-ink in various viscosities, from low to high

- Tailorable mechanical properties: By adjusting parameters such as crosslinking density and polymer concentration, the stiffness, elasticity and strength of gelatin-based constructs can be tailored to accurately mimic the mechanical characteristics of target tissues.