Conventional Metalworking Fluids and Innovative Solutions

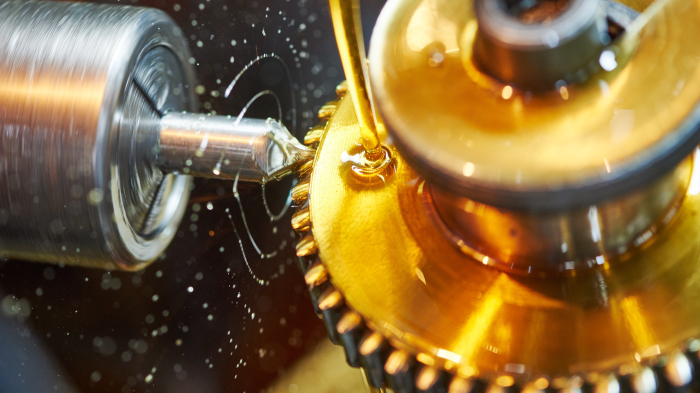

Globally, thousands of tons of metalworking fluids (MWFs) are consumed each year. Those fluids are indispensable for protecting workpieces and equipment against abrasive wear and overheating during lathing, drilling, milling or grinding. Despite an uncertain economic climate, the demand for these fluids has continued to grow steadily.

Traditional metalworking fluids can be classified into three main types: straight oils, soluble oils, and synthetic fluids. Straight oils are petroleum-based and provide excellent lubrication, but they require frequent replacement due to their limited cooling abilities. Soluble oils are a mixture of petroleum oil and water, offering better cooling properties and improved tool life. Synthetic fluids, on the other hand, are chemically formulated and provide superior cooling and lubrication, resulting in extended tool life and improved surface finish. What all traditional types have in common are their environmental impact and health concerns for workers, when not treated and disposed properly.

Introducing NOVOTEC® CL800

GELITA’s NOVOTEC® CL800 is an innovative protein-based liquid concentrate. As a green additive for a new generation of metalworking fluids it adds value to both oil-free (synthetic) and oil-miscible (semi-synthetic) metalworking fluids.